Slurry Cover

Uncovered slurry stores release about thirty percent of farm ammonia and avoidable methane every year.

Storage covers trap gases and keeps nutrients safe until timely spreading.

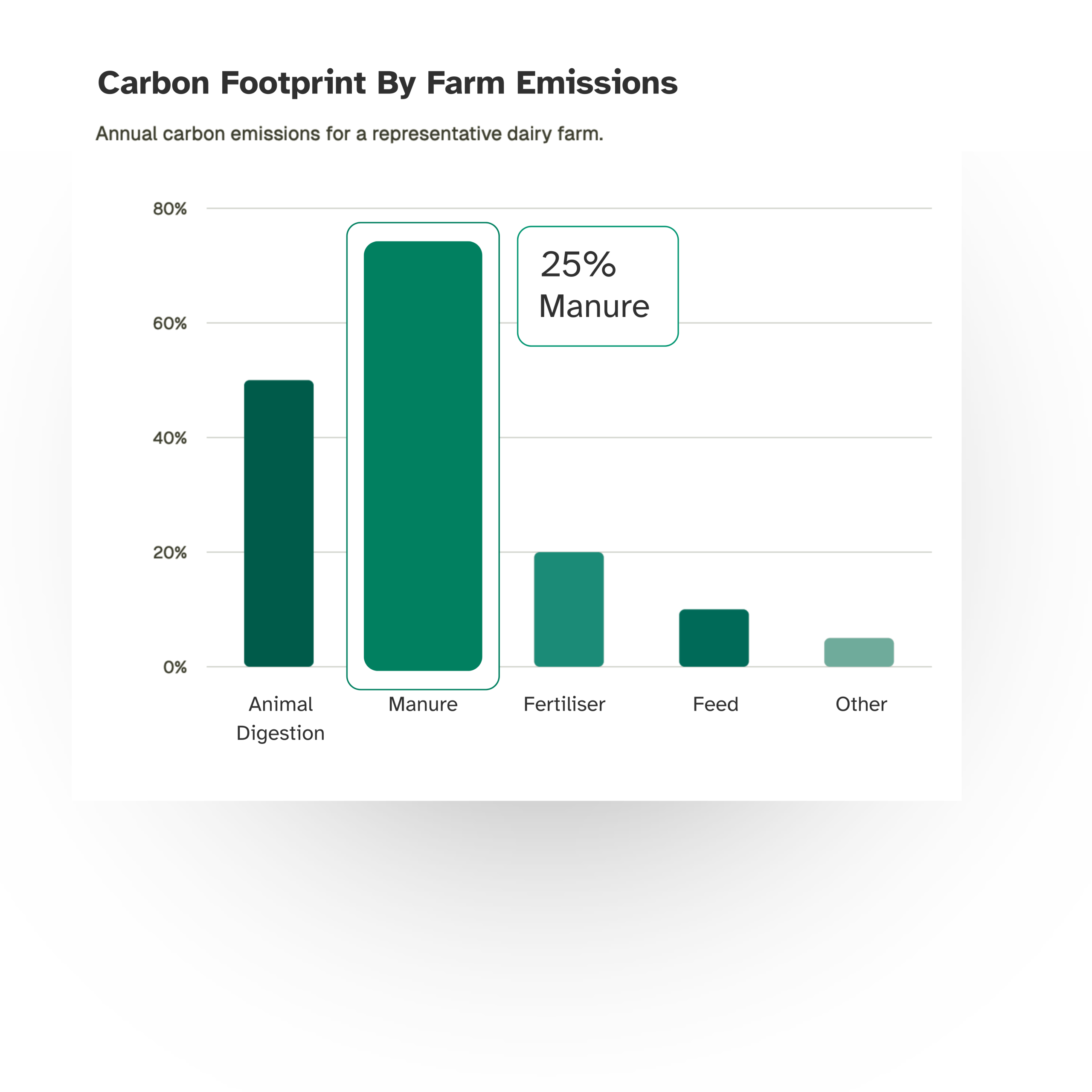

The Climate Issue

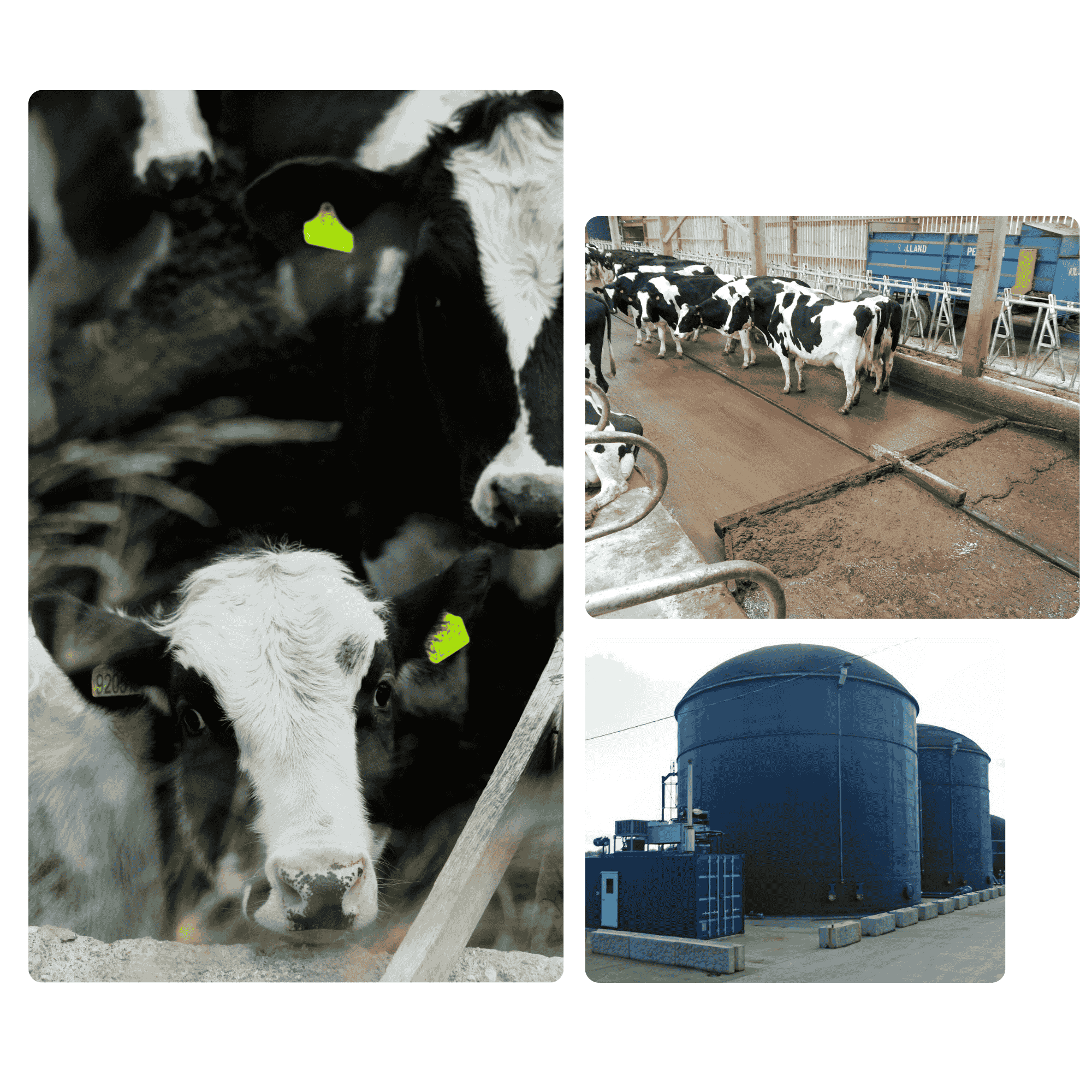

Liquid slurry is central to nutrient cycling on grass farms. Tanks hold the mixture of dung, urine, and wash water produced every day. Holding slurry lets farmers spread at the right time when crops need nitrogen and potassium. Properly stored, it grows grass, replaces chemical fertiliser, and improves soil health over time.

Yet when storage is left open, microbes thrive and warm air meets the slurry surface. Methane bubbles off, and ammonia rises into the wind. Each lost litre wastes nitrogen and carbon, aggravates odour, and breaches clean-air rules now tightening across Europe.

The Solution: Slurry Cover

Slurry storage covers form a sealed lid over tanks or lagoons, separating manure from weather and trapping gases for safe management until planned spreading. By blocking wind and cooling slurry slightly, covers suppress gas formation rates.

Field trials show impermeable lids reduce methane escape by up to ninety percent and cut ammonia loss by forty to eighty percent. The nitrogen boosts fertiliser value and lowers greenhouse-gas footprint of systems.

Key Benefits when using Slurry Storage Cover

Cut Emissions

Solid or flexible covers seal the slurry surface, preventing exchange and slashing both methane and ammonia emissions before they reach atmosphere open.

Keep Nutrients

By holding nitrogen in ammonium form, covered slurry conserves fertiliser value. Farms can spread fewer granules, save money, and grow the same grass from nutrients stored.

Reduce Odours

Covering slurry traps strong smells within the tank, letting farmers locate storage closer to homes and graze animals sooner after each application.

Impact of Slurry Storage Cover

Installing covers on slurry stores is a proven way to reduce emissions, retain valuable nutrients, and support climate compliance. Upfront investment in materials and installation must be considered.

Field studies show that covering all slurry stores can deliver economical and environmentally positive outcomes:

Cut methane emissions by 80-90% during storage

Reduce ammonia emissions by 40–60%, improving nitrogen retention

Save up to €30/ha in synthetic fertiliser (improved slurry nutrient value)

Lower whole-farm GHG intensity by 3–5%, depending on coverage and baseline conditions

Below, we outline the change across three adoption scenarios, using data from Irish dairy herds with covered concrete tanks today.

|

Scenario

|

Price / 1000 gal slurry

|

Fertiliser Net Savings / 50 ha

|

GHG Emissions

|

% GHG Reduction

|

|---|---|---|---|---|

|

0% covered |

€75 |

- |

0.960 kg CO₂-eq/kg milk |

0% kg CO₂-eq/kg milk |

|

50% covered |

€90 |

€1,800 |

0.939 kg CO₂-eq/kg milk |

2% kg CO₂-eq/kg milk |

|

100% covered |

€105 |

€3,600 |

0.912 kg CO₂-eq/kg milk |

5% kg CO₂-eq/kg milk |

Considerations

Structural Integrity

Covered slurry requires strong tanks and secure anchoring. Farmers must check wall strength and access, and may need engineering input. Installation and tank upgrades come with upfront capital costs that should be factored in before committing to a cover.

Gas Management

Covered slurry traps gases, so safe venting or flaring is essential. Systems need pressure-relief valves or biogas pipes to stop ballooning and to direct methane safely for combustion or future energy use on farm.

Maintenance & Regulations

Fabric or rigid lids can tear, degrade, or collect rainwater. Regular inspections, repairs, and record-keeping are required to stay compliant with nitrate rules and to ensure covers perform for their full lifespan.

Implementation

Adding storage covers is a simple upgrade, but long-term success relies on good planning, proper installation, and regular upkeep. The tips below help ensure that your covers perform safely and effectively. They support environmental compliance while boosting overall farm efficiency year-round.

1. Assess tank structure. Before installation, inspect tank walls, roofs, and any agitation points for damage or wear. Seek advice from an engineer if reinforcement or modifications are required.

2. Plan for safe venting. Fit proper gas vents, pressure valves, or flexible pipes to avoid gas build-up. Train staff to monitor conditions and safely release gas during agitation events.

3. Maintain your cover. Check cover tension and condition every season. Repair small tears quickly, remove excess rainwater, and clear debris to keep the system safe, sealed, and effective.

Behind the Research

ODOS Tech was founded by Cian White and Alejandro Vergara, two sustainability specialists with deep expertise in agricultural climate action.

Alejandro (left), a PhD in environmental engineering from University College Dublin, helps farmers measure their carbon footprint and implement mitigation strategies to reduce their impact. Cian (right), a researcher at Trinity College Dublin with a PhD in ecology, works on restoring nature to increase biodiversity on farms using satellite imagery to monitor habitats.

Together, they helped lead the carbon and nature-based work for the Farm Zero C project at Shinagh Farm, one of Europe’s first net-zero dairy pilots. At ODOS, they build smart, science-based tools to help agri-food businesses protect the environment and restore nature.

Research

Teagasc Storage Trials

Teagasc studies on covered slurry tanks report methane reductions up to ninety percent and ammonia cuts of half or more, while maintaining nutrient value and allowing safer agitation during the spreading season.

AgClimatise Policy

Ireland’s AgClimatise roadmap promotes mandatory covering of new slurry stores, providing grant aid for rigid or floating lids and counting the practice toward national ammonia targets under EU Clean-Air rules.

IPCC Manure Guidance

The IPCC lists impermeable covers as a proven manure technology, highlighting their high methane mitigation potential, low maintenance requirements, and compatibility with downstream biogas recovery for renewable heat and power.

Discover other Strategies

Slurry Acidification

Slurry acidification reduces fertiliser demand and cuts emissions by up to 5% during storage and spreading.

Slurry Treatment

Treating slurry with hydrogen peroxide cuts emissions by up to 4% and reduce methane by up to 80% during storage.

Slurry Cover

Covering slurry stores cuts emissions by up to 5% and saves €3,600 over 50 hectares per year by reducing synthetic fertiliser use.

Extending Grazing Season

Extending the grazing season cuts emissions by up to 2.7% and boosts milk revenue by nearly €3,000 per farm.

Antimethanogenic Feed Additives

Antimethanogenic feed additives cut methane emissions by up to 28% and cost €6975 per 93 cows annually.

Grass Biorefinery

Grass biorefineries replace soy protein, save €3,000 in feed costs, and cut emissions by 8.9%.

Anaerobic Digestion

Sending slurry to anaerobic digestion can cut emissions by up to 9.4% and generate up to 400 MWh of energy per year.

Multispecies Swards

Switching to multispecies swards cuts emissions by up to 8.8% and saves €4,400 in fertiliser across 50 hectares.

Red Clover Silage

Using red clover silage cuts emissions by up to 8.2% and saves €2,000 in fertiliser across 20 hectares.

White Clover Silage

Incorporating white clover silage cuts emissions by up to 7.8% and saves €4,500 in fertiliser costs over 50 hectares.

Low Emission Slurry Spreading

Low-emission slurry spreading cuts ammonia by 60% and saves €45/h in fertiliser costs.

Genetic Selection

Genetic selection for high-EBI cows cuts emissions by up to 6.3% and boosts gains by €7,800 per 100 cows.

Protected Urea

Switching to protected urea cuts fertiliser costs and lowers emissions by up to 5.6% per kg of milk.

Ready to reduce emissions through with Slurry Cover?

Talk to our Carbon Footprint & Biodiversity experts on how we can help.