Rethinking Waste: How Biogas Is Transforming Swine Sustainability

Rethinking Waste in Swine Production

In the ever-evolving landscape of agricultural sustainability, few innovations shine as brightly as biogas. For the swine sector, often criticized for its environmental impact, biogas presents not just a solution, but a transformation. This clean energy source, derived from pig manure and slaughterhouse waste, is redefining waste management and climate strategy across Europe. And nowhere is this more evident than in Spain, a powerhouse of pork production, where companies like Campofrío are leading the charge.

The Challenge: Swine Waste and Environmental Impact

Swine farming is one of the most feed-intensive and waste-generating forms of livestock production. Each pig produces a substantial volume of manure, which, if unmanaged, leads to serious environmental issues. Think of nitrate leaching into groundwater, ammonia emissions, and the release of potent greenhouse gases like methane and nitrous oxide.

Regions with dense pig populations, like Catalonia, Murcia, and Aragón, have been under regulatory pressure due to nitrate pollution. Complaints from local communities about smells and pollution have caused some areas to stop farm expansions. Thus, effective waste management is not just a compliance issue; it’s a license to operate.

The Solution: Biogas as a Circular Economy Tool

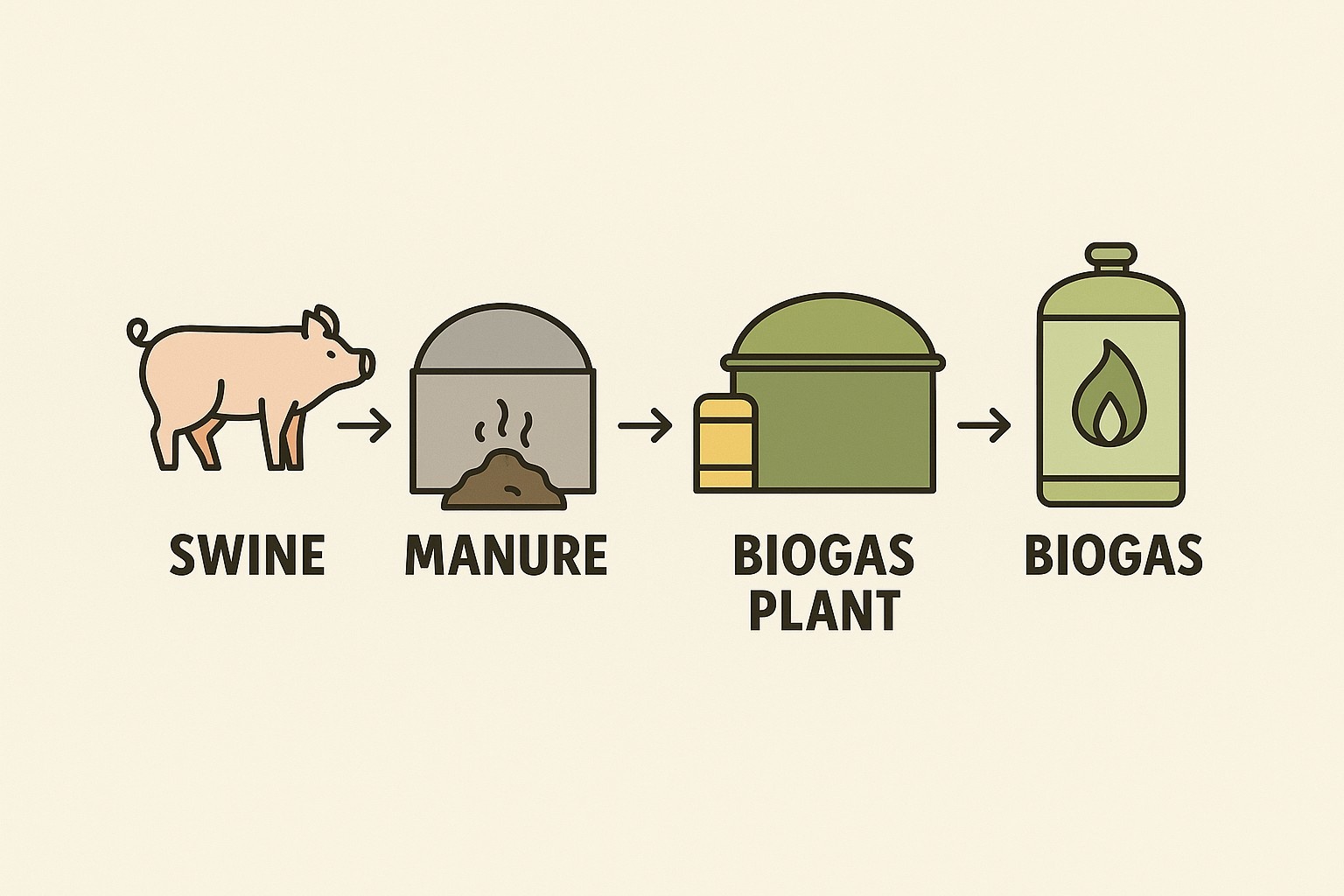

Biogas offers a compelling circular solution. By anaerobically digesting pig manure and organic slaughterhouse waste, farms and processors can generate methane-rich gas used for energy, replacing fossil fuels, powering operations, and reducing emissions. The leftover digestate can be treated and used as a nutrient-rich fertilizer, further closing the loop.

This process involves several key steps:

Manure Collection: Manure is collected from swine facilities, typically stored in slurry form in sealed containers or lagoons to limit emissions.

Feedstock Preparation: The manure, often mixed with organic slaughterhouse byproducts, is prepared as feedstock. This mixture ensures an optimal balance of carbon and nitrogen for microbial activity.

Anaerobic Digestion: The feedstock is introduced into a digester—an oxygen-free environment where specialized bacteria break down the organic matter. This produces biogas (primarily methane and CO2) and digestate.

Biogas Capture and Use: The biogas is captured and either used on-site to power operations (e.g., heating or electricity generation) or upgraded and injected into the natural gas grid. This displaces fossil energy sources.

Digestate Treatment and Reuse: The remaining digestate, rich in nutrients like nitrogen and phosphorus, is treated and can be safely applied to fields as organic fertilizer, reducing dependence on synthetic inputs.

Each step supports the broader goals of reducing emissions, conserving resources, and creating a self-sustaining cycle within pork production.

Campofrío’s flagship project in Burgos, named Biogasnalia, exemplifies this transition. The facility processes approximately 15,000 tons of organic waste annually, producing around 12,000 MWh of biogas and reducing emissions by an estimated 2,400 tonnes of CO2 equivalent each year. This single plant covers roughly 40% of the steam needs for Campofrío’s Burgos site, slashing dependence on fossil fuels and demonstrating measurable climate action.

Broader Adoption Across the Sector

Campofrío is not alone. Integrators like Grupo Fuertes is also investing in large-scale digesters. In highly integrated supply chains like Spain’s, such decisions have wide-reaching effects. If a company mandates biogas systems across its network or partners with farms to share digesters, it can rapidly scale impact.

What makes biogas especially strategic is its multi-dimensional return:

Environmental: Reduces GHG emissions, mitigates nitrate and ammonia release, and supports cleaner air and water.

Economic: Generates on-site energy, lowers utility costs, and may qualify for carbon credits or renewable incentives.

Regulatory: Helps companies meet tightening EU requirements under the Nitrates Directive, Industrial Emissions Directive, and forthcoming CSRD climate disclosures.

Explore how ODOS can help your operation meet EU sustainability targets.

Obstacles and Opportunities

Despite its promise, biogas adoption faces challenges. High upfront investment, technical complexity, and the need for coordinated manure logistics (especially among smaller farms) can be barriers. However, these are being overcome with:

Public subsidies (e.g., EU NextGen funds, regional grants in Spain).

Shared infrastructure models (e.g., co-ops or joint ventures for digesters).

Technological advances in small-scale digesters and monitoring tools.

The Role of Technology: How ODOS Tech Enables Smart Biogas Management

The next evolution in biogas sustainability is digital. ODOS Tech provides specialized tools to measure greenhouse gas emissions reductions from biogas systems with precision and transparency. With ODOS, companies can:

Quantify emissions reductions from manure-to-energy conversion using robust, science-based methodologies.

Generate verified, report-ready emissions data aligned with international standards.

Integrate emissions data into a broader ESG and sustainability framework, fully aligned with CSRD reporting requirements.

For companies like Campofrío, ODOS enables credible emissions accounting from biogas projects, transforming sustainability claims into auditable results.

Conclusion: A Greener Path Forward

As the swine industry faces mounting pressure to decarbonize, biogas stands out as both a mitigation strategy and a business advantage. By harnessing waste and turning it into energy, companies are not only reducing their environmental footprint but also enhancing operational resilience.

The success of pioneers like Campofrío shows what’s possible when innovation meets commitment. With digital tools like ODOS Tech in play, the path to a low-carbon, circular swine sector is not only feasible. It’s already underway.

Ready to measure your biogas impact? Learn how ODOS helps farms and processors quantify emissions reductions with confidence.