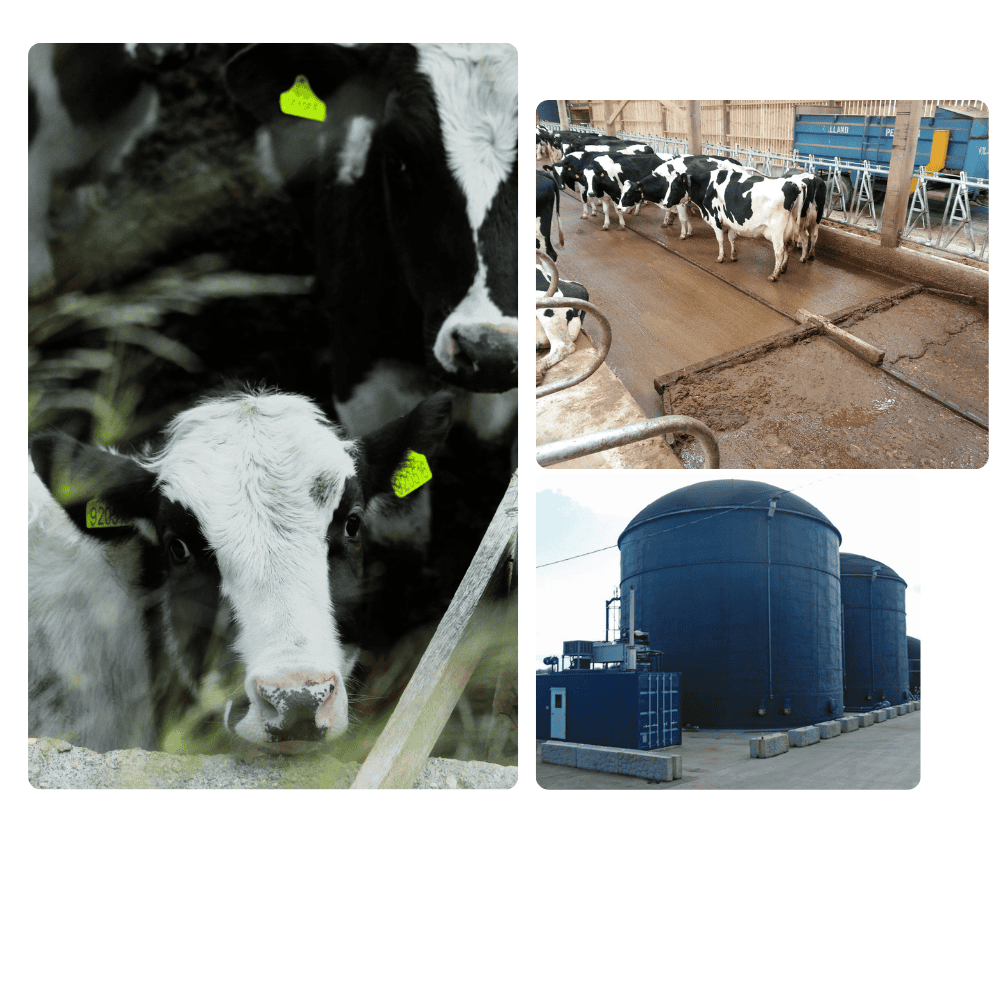

Slurry Acidification

Slurry can lose up to 80 % of its nitrogen if left untreated.

Acidifying slurry locks in nutrients, suppresses emissions, and improves fertiliser value.

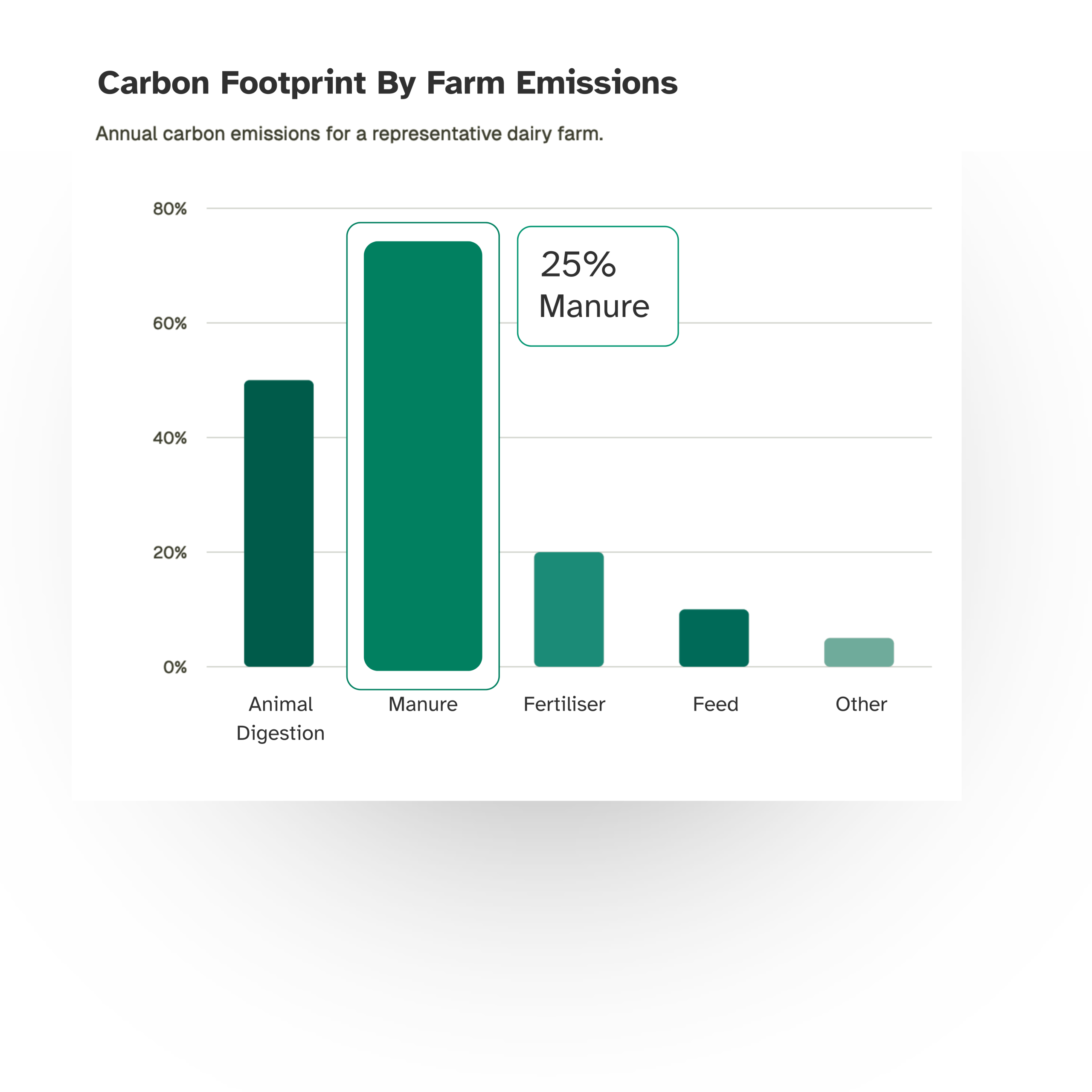

The Climate Issue

Slurry is one of the most valuable but volatile fertilisers on the farm. It contains a rich mix of nitrogen, carbon, and water, but in its untreated form, much of that escapes before crops can use it.

When slurry is stored or spread, bacteria produce methane and ammonia gas. These gases waste nutrients, worsen air quality, and drive up the farm’s greenhouse gas emissions. The pH of the slurry plays a major role in this loss.

In alkaline conditions, nitrogen converts to ammonia and drifts off. When stored warm or for weeks, carbon transforms into methane. This means more pollution, lower value, and weaker fertilising impact per litre.

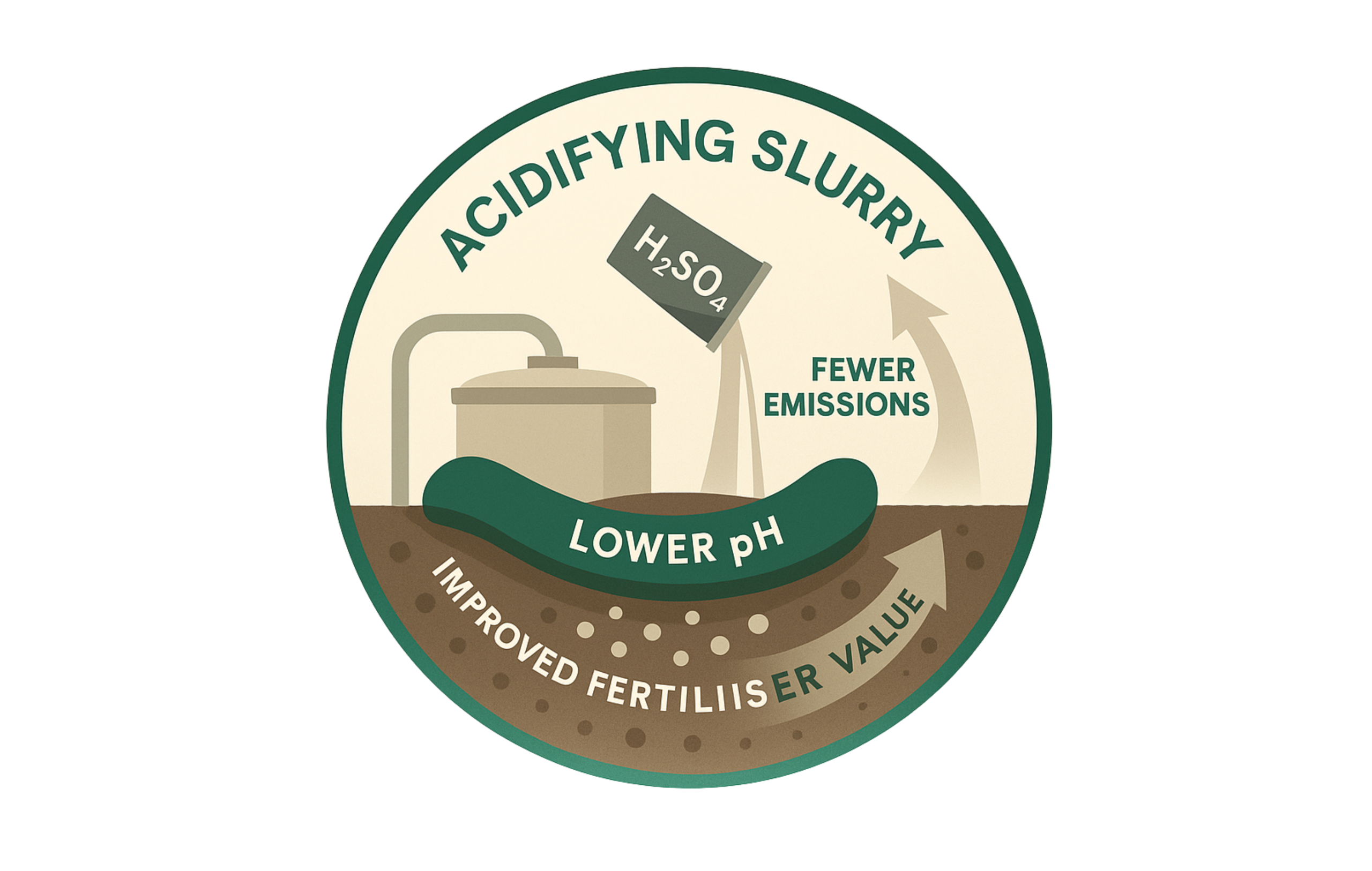

The Solution: Slurry Acidification

Acidification is a smart way to stabilise slurry. It uses a small amount of acid, typically sulfuric acid (H₂SO₄), although alternatives like hydrogen peroxide are also used to lower the pH to around 5.5–6.

Bringing the pH down slows ammonia formation and locks more nitrogen into a stable form. It also suppresses methanogenic bacteria, cutting methane emissions. Treated slurry becomes a more effective and cleaner fertiliser.

Trials show acidification can fully mitigate ammonia loss and reduce methane emissions by up to 80 %. That means fewer air pollutants, more nitrogen in your soil, and stronger grass growth.

Key Benefits when Acidifying Slurry

Cut Emissions

By lowering pH, acidified slurry stops ammonia escaping into the air. It also suppresses methane-forming microbes, cutting emissions during storage and handling.

Fertiliser Value

More nitrogen is retained in a plant-available form. This means higher nutrient use efficiency, less need for synthetic fertiliser, and better yields from the same slurry volume.

Suppress

Lower-pH slurry smells less and inhibits pathogen survival. This improves working conditions and may reduce grazing intervals on treated paddocks.

Impact of Slurry Acidification

Switching to slurry acidification improves environmental performance and fertiliser efficiency. When applied correctly, it’s a cost-effective way to stabilise nutrients, support grass growth, and reduce emissions from storage and spreading.

Farm Zero C, using products like Glasabate, shows that acidification can:

- Reduce methane by 67–90% when the slurry pH is lowered to 5.5–6

- Cut ammonia emissions by 60–95%, depending on acid dose and pH

- Lower indirect N₂O emissions by 10–20% via reduced NH₃ volatilisation

- Retain an extra 1–4 kg of nitrogen per 1,000 gal of slurry, reducing fertiliser demand

To assess environmental and economic impacts, we modelled a 93-cow dairy herd housed for 18 weeks over winter, as shown in the table below.

|

Scenario

|

Quantity of slurry amended (m3)

|

Amendment cost (€)

|

Total Emissions (kg CO2-eq / kg FPCM)

|

% GHG Reduction

|

|---|---|---|---|---|

|

Amend 50% of slurry |

226 |

€452 |

0.935 |

2.56% |

|

Amend 100% of slurry |

552 |

€1104 |

0.911 |

5.10% |

Considerations

Equipment & Storage

Acidification requires dedicated equipment, including acid tanks, mixers, and slurry agitators that can withstand corrosion. Tanks must be sealed and well-managed to avoid structural damage.

Safety Protocols

Sulphuric acid is a hazardous chemical. Safe handling procedures and trained personnel are essential. Acid-resistant gloves, storage areas, and dosing systems are needed to protect workers and animals.

Timing Matters

To get the full benefit, slurry should be acidified shortly after collection or before storage. Acidification just before spreading also improves results, but storage-related emissions will already have occurred.

Implementation

Rolling out acidification on farm requires upfront planning and proper procedures. Follow these tips to apply it safely and effectively, supporting both environmental and agronomic goals.

1. Install acid-safe gear. Use acid-resistant tanks and mixers, and work with suppliers to design a system suitable for your farm scale and slurry type.

2. Follow safety protocols. Store acid securely, wear appropriate PPE, and ensure trained staff handle dosing and agitation during each treatment.

3. Integrate with nutrient plan. Account for retained nitrogen in your fertiliser plan and apply treated slurry on fields with high nutrient demand and good buffer zones.

Behind the Research

ODOS Tech was founded by Cian White and Alejandro Vergara, two sustainability specialists with deep expertise in agricultural climate action.

Alejandro (left), a PhD in environmental engineering from University College Dublin, helps farmers measure their carbon footprint and implement mitigation strategies to reduce their impact. Cian (right), a researcher at Trinity College Dublin with a PhD in ecology, works on restoring nature to increase biodiversity on farms using satellite imagery to monitor habitats.

Together, they helped lead the carbon and nature-based work for the Farm Zero C project at Shinagh Farm, one of Europe’s first net-zero dairy pilots. In 2020, they launched ODOS, a platform that built smart, science-based tools to help agri-food businesses protect the environment and restore nature.

Research

European Acidification Trials

Studies in Denmark and Germany show acidified slurry can cut methane by up to 66 % and ammonia loss by 50 % or more, with no negative impact on grass yield or animal health.

Teagasc Slurry Research

Irish trials confirm that acidified slurry increases the nitrogen use efficiency of manure. Treated slurry delivers better crop response, particularly in spring spreading windows.

IPCC Guidelines

The IPCC recognises acidification as a technically proven option to reduce emissions from livestock manure. It is especially useful where other spreading options are limited, or when storage is a major emission source.

Discover other Strategies

Slurry Acidification

Slurry acidification reduces fertiliser demand and cuts emissions by up to 5% during storage and spreading.

Slurry Treatment

Treating slurry with hydrogen peroxide cuts emissions by up to 4% and reduce methane by up to 80% during storage.

Slurry Cover

Covering slurry stores cuts emissions by up to 5% and saves €3,600 over 50 hectares per year by reducing synthetic fertiliser use.

Extending Grazing Season

Extending the grazing season cuts emissions by up to 2.7% and boosts milk revenue by nearly €3,000 per farm.

Antimethanogenic Feed Additives

Antimethanogenic feed additives cut methane emissions by up to 28% and cost €6975 per 93 cows annually.

Grass Biorefinery

Grass biorefineries replace soy protein, save €3,000 in feed costs, and cut emissions by 8.9%.

Anaerobic Digestion

Sending slurry to anaerobic digestion can cut emissions by up to 9.4% and generate up to 400 MWh of energy per year.

Multispecies Swards

Switching to multispecies swards cuts emissions by up to 8.8% and saves €4,400 in fertiliser across 50 hectares.

Red Clover Silage

Using red clover silage cuts emissions by up to 8.2% and saves €2,000 in fertiliser across 20 hectares.

White Clover Silage

Incorporating white clover silage cuts emissions by up to 7.8% and saves €4,500 in fertiliser costs over 50 hectares.

Low Emission Slurry Spreading

Low-emission slurry spreading cuts ammonia by 60% and saves €45/h in fertiliser costs.

Genetic Selection

Genetic selection for high-EBI cows cuts emissions by up to 6.3% and boosts gains by €7,800 per 100 cows.

Protected Urea

Switching to protected urea cuts fertiliser costs and lowers emissions by up to 5.6% per kg of milk.

Ready to reduce emissions through Slurry Acidification?

Talk to our Carbon Footprint & Biodiversity experts on how we can help.