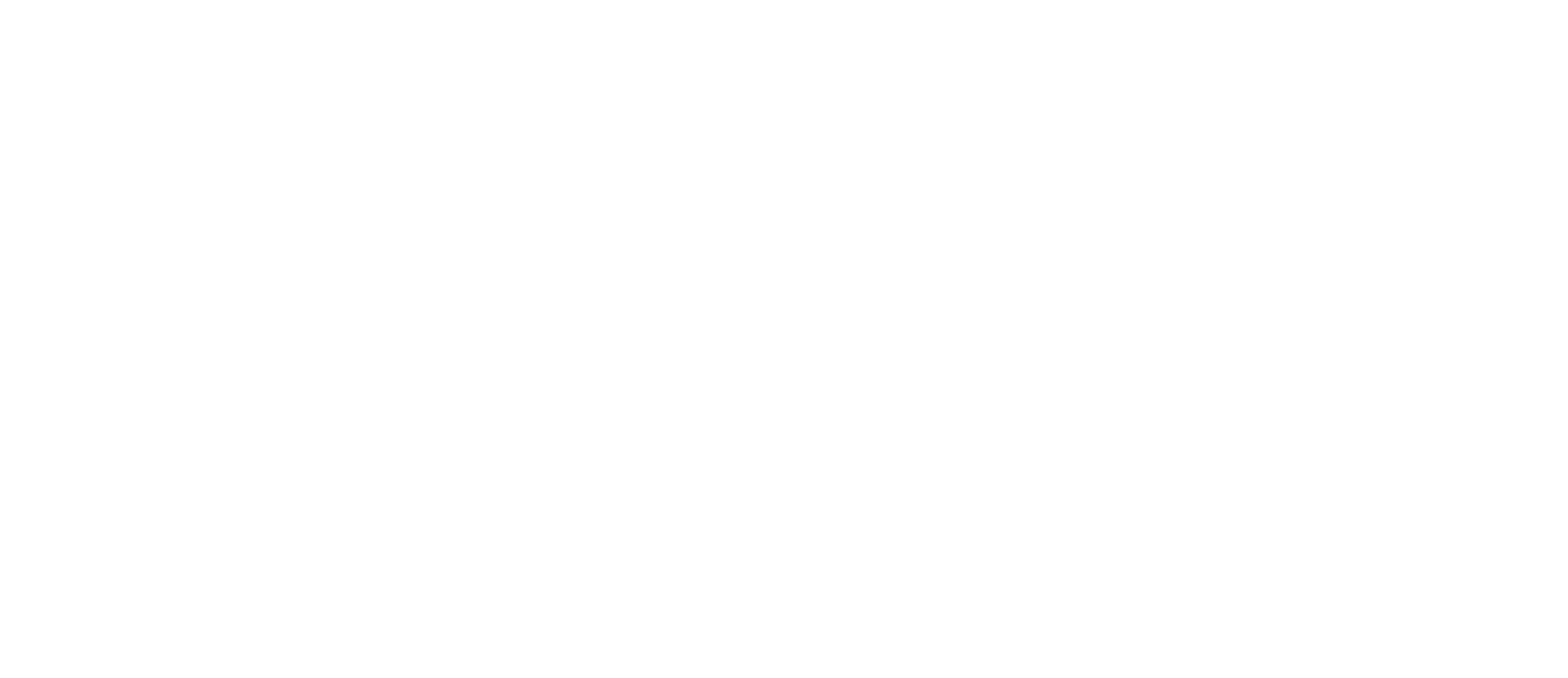

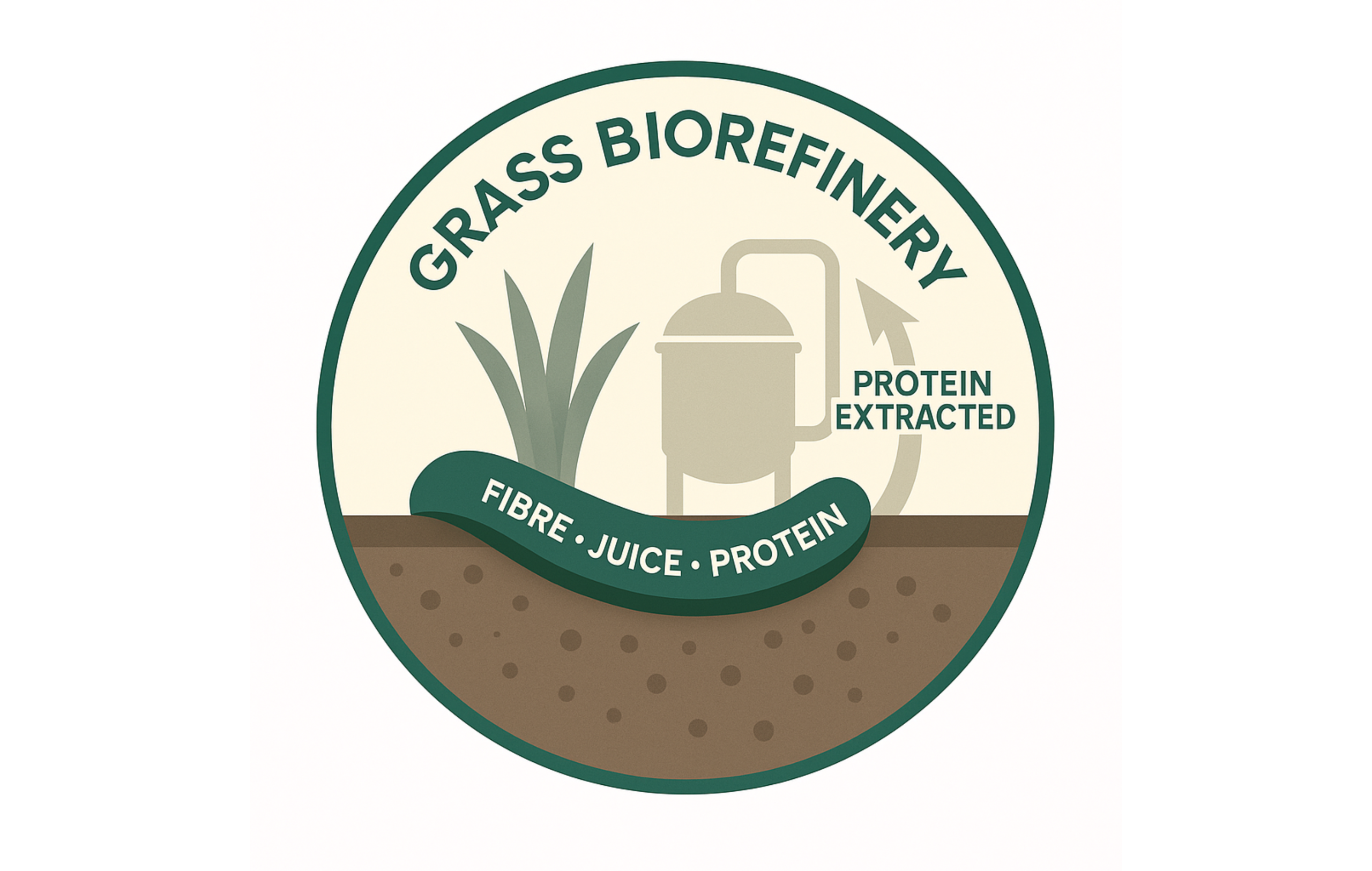

Grass is a useful and renewable resource. But most of it goes straight from the field to the cow. A lot of its protein is lost during digestion or turned into methane, a strong greenhouse gas.

At the same time, Europe imports millions of tonnes of soy and other protein feeds every year. This causes deforestation, adds to global emissions, and makes feed prices less stable for farmers.

We have plenty of grass. But we’re not using its full value as a local, climate-friendly protein source. Using it better could cut imports and lower emissions.