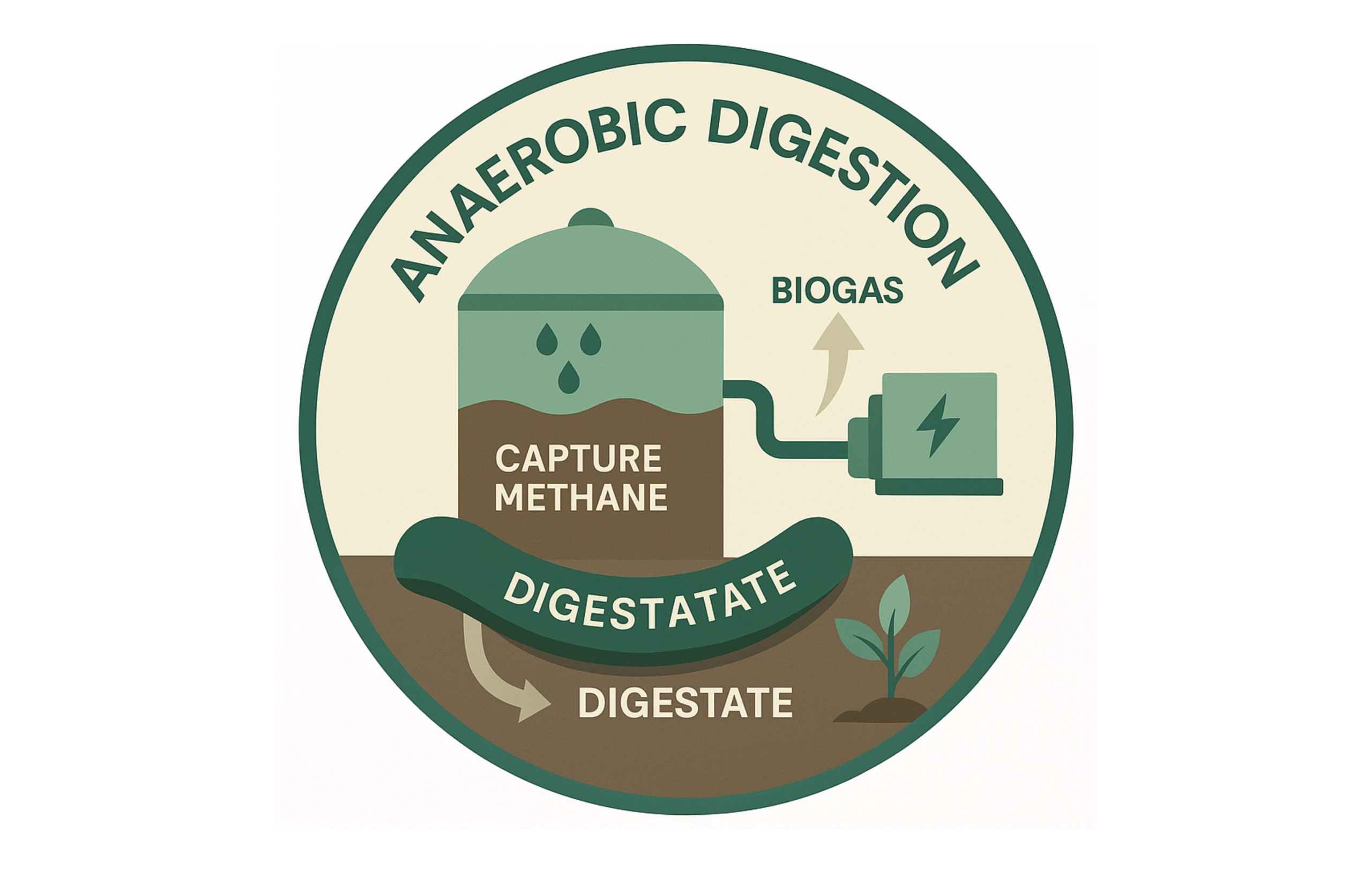

Anaerobic Digestion

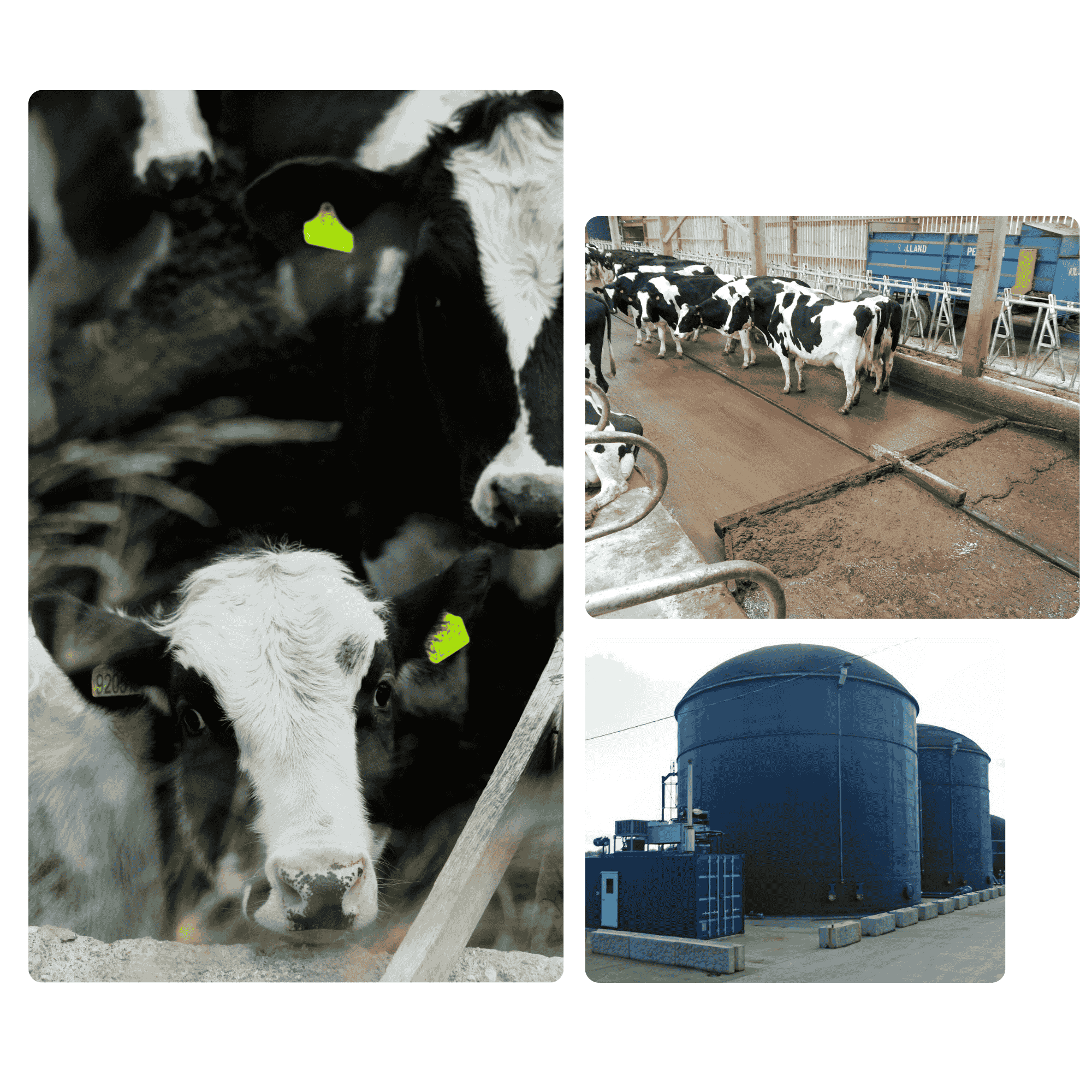

Livestock slurry releases methane and nitrous oxide into the air.

Anaerobic digestion captures these gases and turns them into clean, renewable energy.

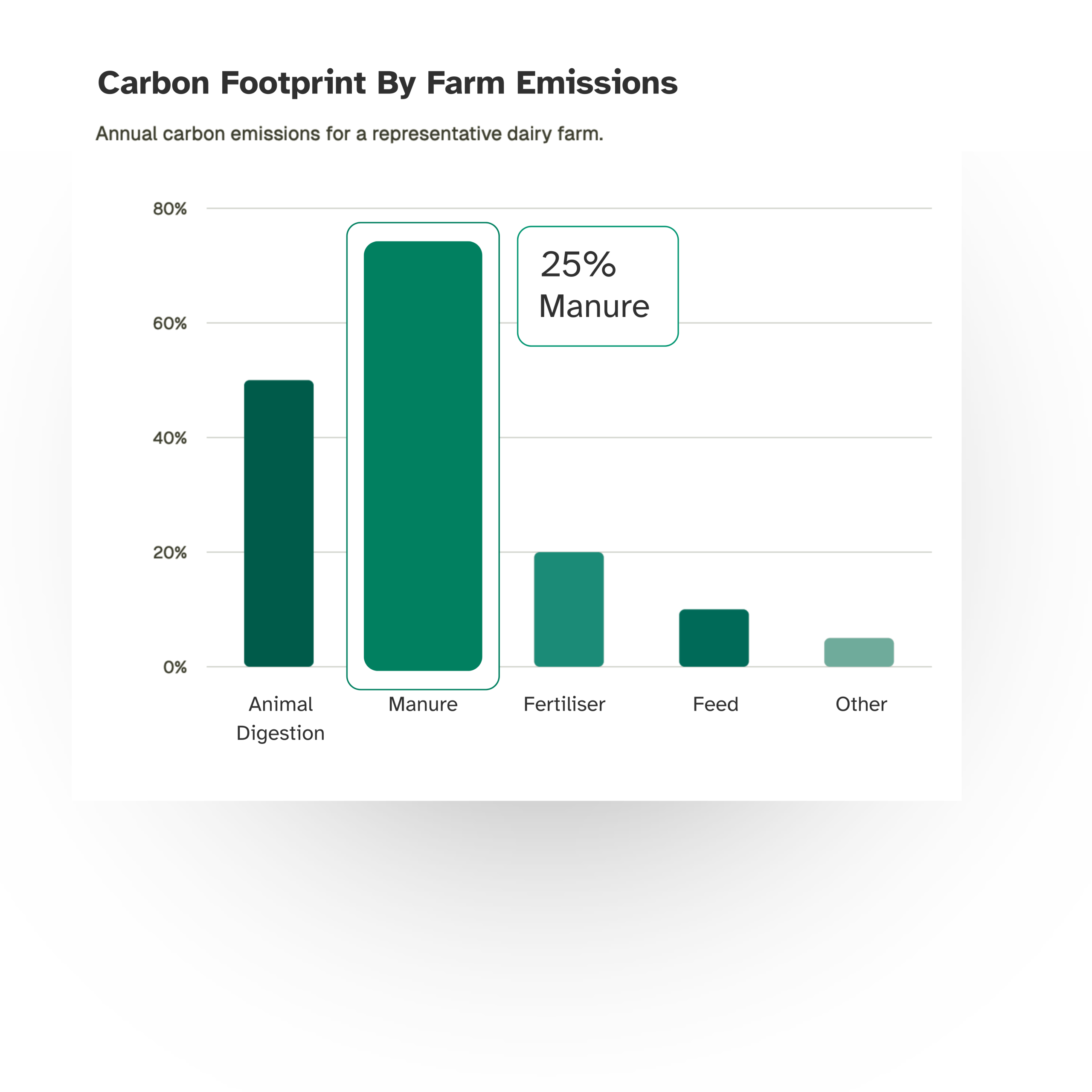

The Climate Issue

Slurry isn’t just waste. It’s a major source of emissions. Left in open tanks or lagoons, it breaks down anaerobically and releases methane, a gas over 80 times more potent than CO₂ in the short term.

Even with careful spreading, slurry contributes nitrous oxide and ammonia, harming air quality and raising the farm’s footprint. Yet this organic material contains valuable energy, if captured before it escapes.

Today, most of that energy is lost into the atmosphere.

The Solution: Anaerobic Digestion

Key Benefits applying Anaerobic Digestion

Cut Methane

Renewable Energy

Fertiliser Use

Digestate is more plant-available than raw slurry, easier to handle, and releases fewer emissions when spread.

Impact of Applying Anaerobic Digestion

Anaerobic digestion (AD) reduces methane emissions during storage, produces biogas that can offset fossil fuel use, and creates digestate that retains fertiliser value. AD also supports nutrient circularity and helps reduce synthetic fertiliser dependence.

Research from Teagasc and EU models shows that AD systems processing 5,000–10,000 tonnes of slurry per year can:

Cut methane emissions by 65–90%

Lower GHG intensity by 0.05–0.09 kg CO₂-eq/kg milk

Generate 200–400 MWh of energy annually

Deliver net benefits only where capital costs, energy prices, and policy supports align

While AD can deliver strong environmental gains, system viability depends on installation costs, energy revenue, and support schemes. Farmers must assess feasibility on a case-by-case basis.

|

Scenario

|

Slurry sent to AD

|

Energy Output (MWh/year)

|

GHG Emissions

|

% GHG Reduction

|

|---|---|---|---|---|

|

0% sent to AD |

- |

- |

0.960 kg CO₂-eq/kg milk |

0% kg CO₂-eq/kg milk |

|

50% sent to AD |

50% |

200 |

0.911 kg CO₂-eq/kg milk |

5.1% kg CO₂-eq/kg milk |

|

100% sent to AD |

100% |

400 |

0.870 kg CO₂-eq/kg milk |

9.4% kg CO₂-eq/kg milk |

Considerations

Capital Investment

Feedstock Volume

Operational Expertise

AD plants require skilled management. Gas handling, digestate storage, and system maintenance are essential for safety and efficiency.

Implementation

1. Assess suitability. Farms with high livestock numbers and sufficient slurry volume are best suited. Consider site access, zoning, and integration with current systems.

2. Explore funding. Look for CAP, EU Innovation, or national renewable energy grants. Group investment with neighbours can help reach a viable scale.

3. Plan for digestate use. Ensure spreading and nutrient plans make full use of the digestate, replacing synthetic fertiliser and closing nutrient loops.

Behind the Research

ODOS Tech was founded by Cian White and Alejandro Vergara, two sustainability specialists with deep expertise in agricultural climate action.

Alejandro (left), a PhD in environmental engineering from University College Dublin, helps farmers measure their carbon footprint and implement mitigation strategies to reduce their impact. Cian (right), a researcher at Trinity College Dublin with a PhD in ecology, works on restoring nature to increase biodiversity on farms using satellite imagery to monitor habitats.

Together, they helped lead the carbon and nature-based work for the Farm Zero C project at Shinagh Farm, one of Europe’s first net-zero dairy pilots. At ODOS, they build smart, science-based tools to help agri-food businesses protect the environment and restore nature.

Research

Teagasc MACC

Farm Zero C Pilot

EU Renewable Energy Strategy

The EU views AD as a key pillar of the Renewable Energy Directive. It supports biomethane development and offers policy incentives for on-farm installations and grid injection.

Discover other Strategies

Slurry Acidification

Slurry acidification reduces fertiliser demand and cuts emissions by up to 5% during storage and spreading.

Slurry Treatment

Treating slurry with hydrogen peroxide cuts emissions by up to 4% and reduce methane by up to 80% during storage.

Slurry Cover

Covering slurry stores cuts emissions by up to 5% and saves €3,600 over 50 hectares per year by reducing synthetic fertiliser use.

Extending Grazing Season

Extending the grazing season cuts emissions by up to 2.7% and boosts milk revenue by nearly €3,000 per farm.

Antimethanogenic Feed Additives

Antimethanogenic feed additives cut methane emissions by up to 28% and cost €6975 per 93 cows annually.

Grass Biorefinery

Grass biorefineries replace soy protein, save €3,000 in feed costs, and cut emissions by 8.9%.

Anaerobic Digestion

Sending slurry to anaerobic digestion can cut emissions by up to 9.4% and generate up to 400 MWh of energy per year.

Multispecies Swards

Switching to multispecies swards cuts emissions by up to 8.8% and saves €4,400 in fertiliser across 50 hectares.

Red Clover Silage

Using red clover silage cuts emissions by up to 8.2% and saves €2,000 in fertiliser across 20 hectares.

White Clover Silage

Incorporating white clover silage cuts emissions by up to 7.8% and saves €4,500 in fertiliser costs over 50 hectares.

Low Emission Slurry Spreading

Low-emission slurry spreading cuts ammonia by 60% and saves €45/h in fertiliser costs.

Genetic Selection

Genetic selection for high-EBI cows cuts emissions by up to 6.3% and boosts gains by €7,800 per 100 cows.

Protected Urea

Switching to protected urea cuts fertiliser costs and lowers emissions by up to 5.6% per kg of milk.

Ready to reduce emissions through Anaerobic Digestion?

Talk to our Carbon Footprint & Biodiversity experts on how we can help.